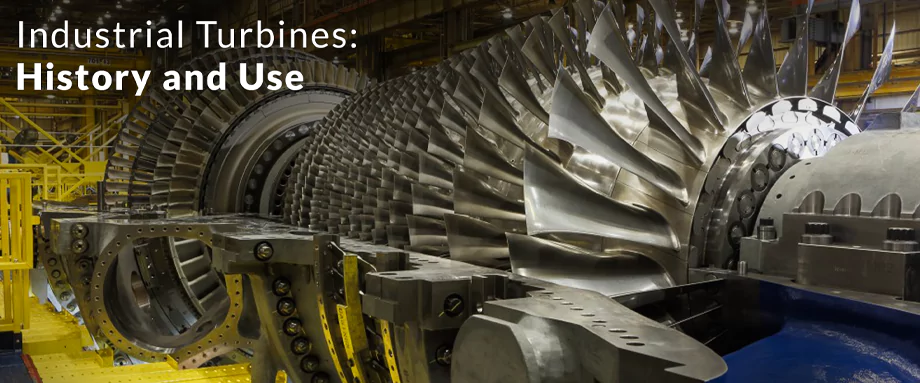

In the vast landscape of industrial machinery, few inventions have played as significant a role as industrial turbines. These remarkable machines have a rich history that dates back centuries and have revolutionized various industries worldwide. This blog will explore industrial turbines' captivating journey, historical development, and diverse modern-day applications. Furthermore, we will examine how Industrial Control Care has contributed to these powerful devices' efficient and safe operation.

What Is It?

Industrial turbines are machines used to convert the energy of a fluid (such as steam, gas, or water) into mechanical energy. They are commonly used in power generation plants, refineries, chemical plants, and other industrial applications.

There are two main types of industrial turbines:

Steam Turbines: Steam turbines are the most common type of industrial turbine. They use high-pressure steam as the working fluid. The steam passes through a series of stationary and rotating blades, causing the rotor to spin. The rotation of the rotor is used to generate mechanical energy, which can then be used to drive generators and produce electricity.

Gas Turbines: Gas turbines, also known as combustion turbines, use a continuous flow of fuel (typically natural gas) and compressed air. The fuel and air mixture is ignited, producing high-temperature, high-pressure gases. These gases expand through stationary and rotating blades, driving the rotor and generating mechanical energy. Gas turbines are widely used for propulsion in power plants and the aviation industry.

Industrial turbines are designed to handle large flow rates and high temperatures and pressures. They are typically built to withstand heavy-duty operation. They are often used in combined cycle power plants, where gas and steam turbines are used together to maximize energy efficiency.

These turbines are crucial in generating electricity and powering various industrial processes, contributing to the overall energy infrastructure and supporting industrial operations worldwide.

The Birth of Industrial Turbines:

The story of industrial turbines begins with the pioneering work of engineer Gustaf de Laval in the late 19th century. De Laval's groundbreaking steam turbine design paved the way for a new era in power generation and industrial processes. Steam turbines quickly gained popularity due to their high efficiency and ability to convert thermal energy into mechanical power.

Evolution and Diversification:

As the power demand grew, so did the need for more advanced and versatile turbines. Over time, engineers and innovators introduced numerous improvements and variations to meet specific industry requirements. Gas turbines, for instance, emerged as an alternative to steam turbines, utilizing fuel combustion to generate mechanical energy. These gas turbines found power generation, aviation, and oil and gas industries applications.

Industrial Control Care (ICC): Ensuring Efficiency and Safety

In the modern era, industrial turbines have become increasingly sophisticated, incorporating advanced technologies and control systems for optimal performance. One prominent name in this realm is Industrial Control Care (ICC), a leading comprehensive industrial control solutions provider.

Industrial Control Care has played a pivotal role in enhancing the efficiency and safety of industrial turbines through its innovative products and services. Their expert engineers specialize in designing and implementing control systems tailored to the unique needs of different turbines. From automated monitoring and diagnostic systems to real-time data analysis, Industrial Control Care ensures that turbines operate at peak efficiency, minimizing downtime and maximizing productivity.

Applications of Industrial Turbines:

Industrial turbines find applications across various industries today, making them indispensable for countless processes. Let's explore some key areas where these powerful machines are employed:

Power Generation: Industrial turbines, both steam, and gas, are extensively used in power plants to produce electricity efficiently. These turbines provide a reliable and environmentally friendly means of meeting the energy demands of communities and industries worldwide.

Oil and Gas Industry: Turbines are critical in the oil and gas sector. They drive compressors for gas pipelines, power drilling rigs, and provide energy for various refining processes.

Aviation: Gas turbines, known as jet engines, propel commercial and military aircraft, enabling rapid transportation across the globe. Developing more fuel-efficient and quieter turbines has greatly contributed to the aviation industry's growth and sustainability.

Manufacturing: Industrial turbines are employed in manufacturing processes such as metalworking, chemical production, and paper manufacturing. They provide the necessary power to drive heavy machinery and facilitate large-scale production.

Wrapping Up:

The evolution of industrial turbines has been a remarkable journey, shaping the progress of numerous industries and improving our lives in countless ways. From Gustaf de Laval's steam turbine to the cutting-edge advancements of today, these machines have truly transformed the world of power generation and industrial processes.

With Industrial Control Care's innovative solutions and expertise, the efficiency and safety of industrial turbines have reached new heights. As we look ahead, the continuous development and integration of control systems will unlock further potential for these remarkable machines, enabling a sustainable and productive future.

Whether it's powering our cities, driving air travel, or propelling industrial processes, industrial turbines, and Industrial Control Care stand at the forefront, playing a vital role in shaping our modern world.