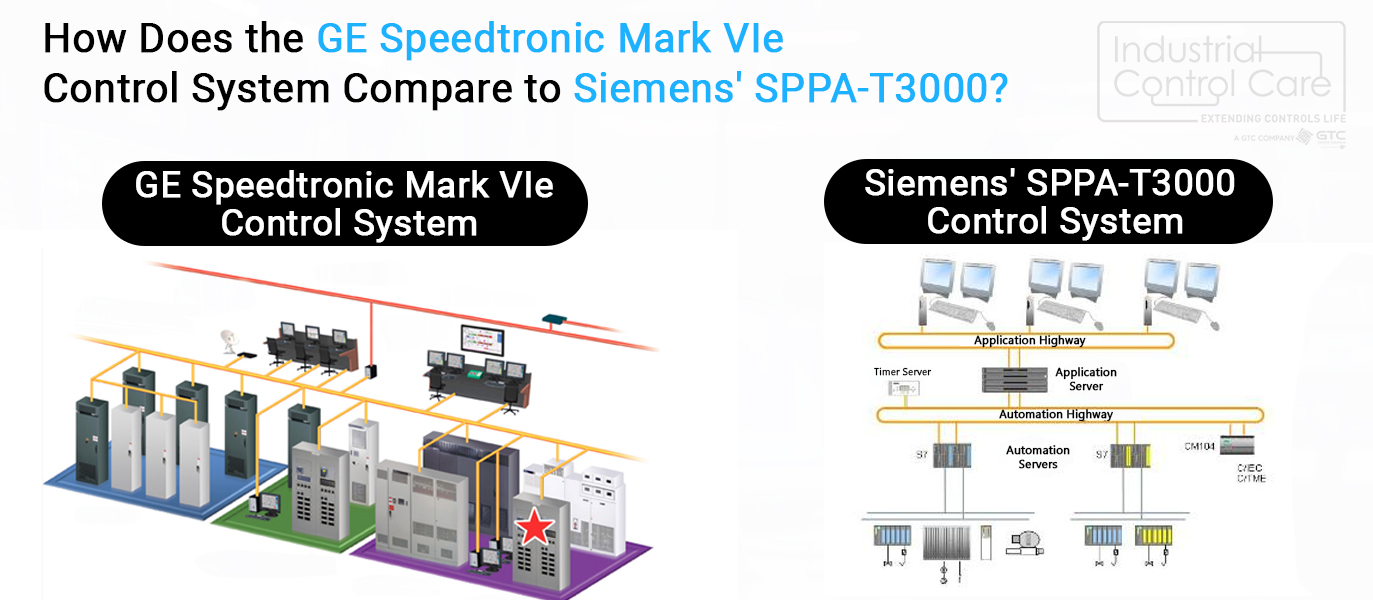

In power generation, advanced control

systems are crucial in ensuring efficiency, reliability, and safety. GE's

Speedtronic Mark VIe and Siemens'

SPPA-T3000 are prominent players in this field. Both systems are designed to

manage and optimize the performance of gas and steam turbines, but they come

with distinct features, capabilities, and benefits. This blog delves into a

comparative analysis of these two control systems, helping industry

professionals make informed decisions.

System Architecture

GE Speedtronic Mark VIe:

The Mark VIe control system is part of

GE's Speedtronic series and was designed specifically for the power generation

industry. It features a distributed control architecture that enhances

reliability and performance. The system employs a centralized controller with

distributed input/output (I/O) modules, allowing for flexible configuration and

scalability. This modular design ensures easy maintenance and upgrades,

reducing downtime and operational costs.

Siemens SPPA-T3000:

The Siemens SPPA-T3000 control system

also boasts a distributed architecture but emphasizes a more integrated

approach. The system integrates control, monitoring, and diagnostics into a

single platform, providing a holistic view of plant operations. Siemens' system

architecture is designed to simplify data management and improve the speed of

data exchange, leading to faster decision-making and enhanced operational

efficiency.

Functionality

GE Speedtronic Mark VIe:

The Mark VIe system is renowned for

its robust control capabilities. It offers advanced process control, turbine

control, and protection functions tailored for gas, steam, and hydro

turbines. The system supports complex control algorithms and provides extensive

diagnostic tools to monitor equipment health and performance. Its flexibility

allows for seamless integration with various turbine models and plant

configurations.

Siemens SPPA-T3000:

The SPPA-T3000 system provides a

comprehensive suite of control functions, including turbine, boiler, and

balance of plant (BOP) control. Siemens emphasizes the importance of predictive

maintenance and incorporates sophisticated diagnostic and prognostic tools to

predict potential issues before they lead to failures. The system's integrated

approach ensures that all components work harmoniously, optimizing overall plant

performance.

User Interface

GE Speedtronic Mark VIe:

The Mark VIe control system features

the ControlST software suite, which provides a user-friendly interface for

operators and engineers. The software offers intuitive graphical displays,

trend analysis, and customizable dashboards, making monitoring and controlling

plant operations easy. ControlST also includes powerful configuration and

diagnostic tools that enhance user experience and streamline workflow.

Siemens SPPA-T3000:

Siemens' SPPA-T3000 system is known

for its advanced Human-Machine Interface (HMI) capabilities. The system uses

the Plant Operator's Interface (POI), which offers a highly intuitive and

customizable user interface. The POI provides real-time data visualization,

trend analysis, and alarm management, enabling operators to make informed

decisions quickly. Additionally, the system's web-based interface allows for

remote access, providing flexibility and convenience.

Performance and Reliability

GE Speedtronic Mark VIe:

GE's Mark VIe control system is

designed to focus on reliability and high performance. The system's distributed

architecture and robust hardware ensure minimal downtime and high availability.

Its advanced control algorithms and diagnostic tools help optimize turbine

performance and extend the lifespan of critical components. GE's extensive

experience in the power generation industry adds to the credibility and

reliability of the Mark VIe system.

Siemens SPPA-T3000:

The Siemens SPPA-T3000 system is

equally focused on delivering top-notch performance and reliability. The

system's integrated approach and advanced diagnostic capabilities contribute to

its high reliability and efficiency. Siemens' commitment to innovation and

quality ensures that the SPPA-T3000 remains a leading choice for power plant

automation. The system's ability to predict and prevent potential issues

further enhances its reliability.

How Does The Mark Vie Handle Turbine Control?

The Mark VIe control system is

renowned for its sophisticated and comprehensive turbine control capabilities.

Here's how it handles turbine control:

Advanced Control Algorithms: The Mark VIe utilizes advanced control

algorithms tailored for various types of turbines, including gas, steam, and

hydro turbines. These algorithms optimize turbine performance, efficiency, and

safety by precisely managing variables such as speed, temperature, pressure,

and load.

Flexible Configuration: The system's modular design allows for

flexible configuration, making it suitable for various turbine models and plant

configurations. This adaptability ensures that the Mark VIe can be customized

to meet the specific operational requirements of different turbines, enhancing

overall control precision.

Real-Time Monitoring and Diagnostics: Mark VIe's standout features are real-time

monitoring and diagnostic capabilities. The system continuously monitors

turbine parameters and conditions, providing operators real-time data and alerts.

This enables proactive management of potential issues and helps maintain

optimal turbine performance.

Integrated Safety and Protection: Safety is a paramount concern in turbine

operation, and the Mark VIe addresses this with integrated safety and protection

functions. The system includes built-in mechanisms for overspeed protection,

temperature control, and vibration monitoring. These features ensure the

turbine operates within safe limits, preventing damage and ensuring long-term

reliability.

Seamless Integration with Plant Systems: The Mark VIe is designed to seamlessly

integrate with other plant control systems, such as Distributed Control Systems

(DCS) and Supervisory Control and Data Acquisition (SCADA) systems. This

interoperability ensures that turbine control is harmonized with overall plant

operations, facilitating coordinated and efficient plant management.

User-Friendly Interface: ControlST, the software suite for the Mark

VIe, provides a user-friendly interface that simplifies turbine control.

Operators can easily configure, monitor, and adjust turbine parameters through

intuitive graphical displays and dashboards. The software also includes

powerful tools for trend analysis and data visualization, aiding

decision-making and performance optimization.

Proven Reliability: With decades of experience in the power

generation industry, GE has designed the Mark VIe to deliver exceptional

reliability. The system's robust hardware and software components are built to

withstand the demanding conditions of turbine operation, ensuring consistent

and dependable performance.

The GE Speedtronic

Mark VIe handles turbine control with advanced control algorithms, flexible

configuration, real-time monitoring, integrated safety features, seamless

integration, and a user-friendly interface. These capabilities make it a robust

and reliable solution for optimizing turbine performance and ensuring safe and

efficient plant operations.

How Does Mark Vie Handle Load Changes In A Power Plant?

Load changes are a critical aspect of

power plant operations, and the Mark VIe control system is specifically

designed to handle these fluctuations efficiently and reliably. Here's how it

manages load changes:

Dynamic Load Adjustment: The Mark VIe employs dynamic load adjustment

capabilities to respond quickly and accurately to load changes. Advanced

control algorithms continuously monitor load demand and adjust turbine output

accordingly. This real-time responsiveness ensures that the power plant can maintain

a stable and consistent power supply, even during sudden load shifts.

Adaptive Control Strategies: The Mark VIe utilizes adaptive control

strategies to manage varying load conditions effectively. These strategies

include load forecasting and predictive control, allowing the system to

anticipate load demand changes and proactively adjust turbine operations. This

minimizes the impact of load changes on plant performance and helps maintain

optimal efficiency.

Automatic Load Shedding and Load Following: The Mark VIe system incorporates automatic

load shedding and features. To prevent overloading, automatic load shedding

ensures that non-critical loads are reduced or disconnected during peak demand

periods. Load following, on the other hand, enables the turbine to adjust its

output to match the load demand dynamically. These features work together to

balance supply and demand effectively.

Seamless Integration with Grid Management

Systems: The Mark VIe control system

is designed to integrate seamlessly with grid management systems. This

integration allows for coordinated control between the power plant and the

electrical grid, ensuring that load changes are managed smoothly. The system

can communicate with grid operators to receive real-time load data and adjust

turbine output to match grid requirements.

Enhanced Stability and Reliability: The ability to handle load changes is crucial

for maintaining plant stability and reliability. The Mark VIe system's robust

control algorithms and real-time monitoring capabilities ensure that load

changes are managed without compromising the stability of the turbine or the

overall plant. This reliability is essential for preventing power outages and

ensuring continuous operation.

User-Friendly Load Management Tools: The ControlST software suite provides

operators access to user-friendly load management tools. These tools provide

real-time data visualization, trend analysis, and customizable dashboards,

making monitoring and managing load changes easy. Operators can quickly adjust

control parameters and respond to load variations, enhancing overall plant

performance.

Proactive Fault Detection and Mitigation: The Mark VIe system includes proactive fault

detection and mitigation capabilities that help manage load changes more

effectively. By continuously monitoring turbine and plant conditions, the

system can detect potential issues that might arise from load changes and take

corrective actions before they escalate. This proactive approach minimizes

downtime and maintains operational continuity.

The GE Speedtronic Mark

VIe handles load changes in a power plant with dynamic load adjustment,

adaptive control strategies, automatic load shedding, seamless grid

integration, enhanced stability, user-friendly tools, and proactive fault

detection. These features ensure the power plant can respond efficiently to

load variations, maintaining reliable and stable operations.

How Does Mark VIe Handle Emergency Shutdowns?

Emergency shutdowns are critical

safety measures in power plant operations, and the Mark VIe control system is

engineered to handle such situations swiftly and effectively. Here's how it

manages emergency shutdowns:

Built-in Safety Protocols: The Mark VIe control system incorporates

built-in safety protocols to detect and respond to emergencies. These protocols

include overspeed protection, high-temperature limits, and abnormal vibration

detection. When triggered, these safety mechanisms initiate an emergency

shutdown to prevent equipment damage or personnel injury.

Rapid Response Time: In an emergency, the Mark VIe system rapidly

responds to initiate the shutdown process. Advanced algorithms continuously

monitor critical parameters and can detect deviations from normal operating

conditions within milliseconds. This swift response ensures the turbine is shut

down promptly to mitigate potential hazards.

Redundant Control Systems: The Mark VIe control system often features

redundant control systems to enhance reliability and redundancy. These

redundant systems operate in parallel, monitoring and controlling turbine operations

simultaneously. In a failure or emergency, the redundant system seamlessly

takes over control, ensuring uninterrupted operation and minimizing downtime.

Integration with Safety Systems: The Mark VIe control system integrates

seamlessly with safety systems and emergency shutdown mechanisms installed

throughout the power plant. This integration allows for coordinated responses

to emergencies, ensuring that all relevant systems are engaged simultaneously

to mitigate risks effectively.

Alarm Management and Notification: Besides initiating the emergency shutdown

process, the Mark VIe system provides comprehensive alarm management and

notification capabilities. Operators are alerted immediately to the emergency

through visual and audible alarms and real-time notifications on control panels

and monitoring screens. This rapid notification enables operators to take swift

action and implement emergency procedures.

Post-Shutdown Analysis and Diagnostics: Following an emergency shutdown, the Mark VIe

system conducts post-shutdown analysis and diagnostics to assess the cause of

the emergency and identify any underlying issues. This analysis helps operators

understand the root cause of the shutdown and take corrective actions to

prevent similar incidents in the future. Additionally, the system generates

detailed reports for regulatory compliance and operational review.

Operator Training and Emergency Procedures: The Mark VIe control system includes

comprehensive operator training modules and procedure manuals to ensure that

personnel are well-prepared to handle emergencies. Training simulations and

drills familiarize operators with emergency shutdown protocols, enabling them

to respond quickly and effectively when necessary.

The GE Speedtronic Mark VIe handles

emergency shutdowns in power plants with built-in safety protocols, rapid

response times, redundant control systems, integration with safety systems,

alarm management, post-shutdown analysis, and operator training. These features

ensure that emergencies are managed efficiently, minimizing risks to personnel

and equipment while maintaining plant safety and reliability.

How Quickly Can Mark VIe Execute An Emergency Shutdown?

The GE Speedtronic Mark VIe control

system is engineered to execute emergency shutdowns with remarkable speed and

precision. Here's a closer look at its rapid shutdown capabilities:

Millisecond Response Time: The Mark VIe control system boasts an

impressively fast response time, detecting deviations from normal operating

conditions within milliseconds. This instantaneous detection allows the system

to initiate the emergency shutdown process with minimal delay, reducing the

risk of equipment damage or personnel injury.

High-Speed Control Algorithms: The Mark VIe utilizes high-speed control

algorithms optimized for swift decision-making and action. These algorithms

continuously monitor critical parameters such as turbine speed, temperature,

and vibration levels, enabling the system to identify potential emergencies and

activate the shutdown sequence within microseconds.

Parallel Processing and Redundancy: The Mark VIe often features parallel

processing and redundant control systems to enhance its speed and reliability

further. Multiple control processors operate in parallel, monitoring and

controlling turbine operations simultaneously. In an emergency, the redundant

system seamlessly takes control, ensuring uninterrupted operation and

minimizing response time.

Instantaneous Actuation of Safety Mechanisms: Upon detecting an emergency, the Mark VIe

control system triggers instantaneous actuation of safety mechanisms such as

overspeed protection, high-temperature limits, and abnormal vibration

detection. These safety mechanisms engage within microseconds, initiating the

shutdown sequence to keep the turbine safe.

Seamless Integration with Safety Systems: The Mark VIe integrates seamlessly with

safety systems and emergency shutdown mechanisms installed throughout the power

plant. This integration ensures that all relevant systems are engaged

simultaneously, facilitating coordinated responses to emergencies and further

reducing shutdown time.

Continuous Monitoring and Predictive

Analytics: The Mark VIe continuously monitors

turbine operations and employs predictive analytics to anticipate potential

emergency scenarios. By analyzing historical data and trends, the system can

proactively identify conditions that may lead to emergencies and take

preemptive action to prevent them. This proactive approach minimizes the

likelihood of emergency shutdowns and enhances overall plant safety.

Why Choose Industrial Control Care For GE Speedtronic

Mark VIe Control System?

Selecting the right partner to

maintain and optimize your GE Speedtronic Mark VIe control system ensures your

power plant operations' efficiency, reliability, and longevity. At Industrial

Control Care, we offer unparalleled expertise and comprehensive services that

make us the ideal choice for your Mark VIe needs. Here's why you should choose

us:

Extensive Expertise: We have a team of highly skilled engineers

and technicians with extensive experience in GE Speedtronic Mark VIe control

systems. Our deep understanding of the system's architecture, functionality,

and intricacies allows us to provide top-notch support and solutions tailored

to your needs.

Customized Solutions: Every power plant has unique requirements,

and we specialize in delivering customized solutions that address your specific

challenges and goals. Our tailored approach ensures optimal performance and

efficiency, whether system upgrades, configuration changes, or troubleshooting.

Comprehensive Services: Our range covers all aspects of the Mark VIe

control system, including installation, commissioning, maintenance, upgrades,

and training. We offer end-to-end solutions that ensure your control system

operates at peak performance throughout its lifecycle.

Rapid Response and Support: Our rapid response team is available 24/7 for

immediate support in an issue or emergency. We understand the critical nature

of power plant operations and are committed to minimizing downtime and ensuring

quick resolution of any problems.

Proactive Maintenance and Monitoring: We offer proactive maintenance services,

including regular inspections, diagnostic checks, and performance monitoring.

Our proactive approach helps identify and address potential issues before they

escalate, ensuring uninterrupted operations and extending the lifespan of your

equipment.

Cost-Effective Solutions: We understand the importance of

cost-efficiency in power plant operations. Our services are competitively

priced, and we focus on delivering solutions that provide the best value for

your investment. Our goal is to enhance your system's performance while keeping

costs manageable.

Proven Track Record: Industrial Control Care is a trusted name in the industry

with a proven track record of successful projects and satisfied clients. Our

commitment to quality, reliability, and customer satisfaction has earned us an

excellent reputation.

Choosing Industrial Control Care for

your GE Speedtronic Mark VIe control system ensures access to extensive

expertise, customized solutions, comprehensive services, rapid support,

proactive maintenance, advanced training, cost-effective solutions, and a

proven track record. We are dedicated to helping you achieve optimal

performance and reliability in your power plant operations.

Wrapping Up:

The GE Speedtronic Mark VIe and

Siemens SPPA-T3000 control systems offer advanced features and capabilities

that cater to the demanding needs of power generation facilities. While the

Mark VIe system stands out with its modular design and robust control

functions, the SPPA-T3000 excels in its integrated approach and predictive

maintenance capabilities.

Choosing between these two systems ultimately depends on the specific requirements of a power plant, including factors such as scalability, ease of use, and integration capabilities. Both GE and Siemens have a strong track record of delivering reliable and high-performance control systems, making either choice a sound investment for optimizing plant operations and ensuring long-term success.